operation & maintenance

overview

O&M

- With over 3 decades of successful endeavors with most of the major companies in the Oil and Gas industry, OCSISNL has made a mark in this industry as a long-term Oil & Gas service provider.

- Present service spectrum of OCSISNL (ICM, TCM and MRO) along with technology solutions, ensures Minimum Total Cost of Ownership (TCO) and provide maximum value to the client.

- Association with BW Offshore enables OCSISNL to access its entire management systems, experiences, operational learnings, technical expertise local content management and country specific learnings.

- With companies moving towards cost effective solution, positioning of OCSISNL with offices in India, Dubai & Singapore makes it a cost effective contender.

- Well established EAM (Enterprise Asset Management System) to provide effective and efficient Operation and Maintenance Management System

- Strategic tie-ups with OEMs and specialized service training agencies to ensure highest levels of individual competency.

- OCSISNL invests in new technological solutions, to maintain strategic advantage.

Learn more about our Operation & Maintenance solutions. Get In Touch

People

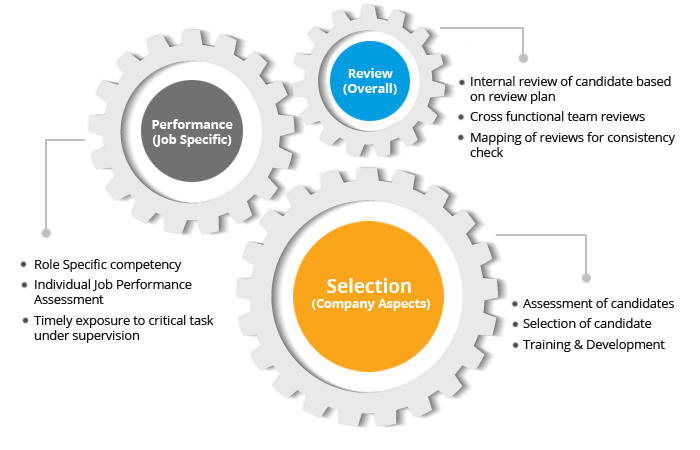

Competency Development & Assurance

- Three staged selection process

- Personal interview and evaluation by Subject Matter Experts

- Aligning the new personnel with the company standards

- Maintaining highest quality of manpower

- Refresher courses and training modules based on job portfolio

- Job rotations to ensure continuous learning curve

- Assurance of personnel effectiveness based on accountability in the offshore environment

Process

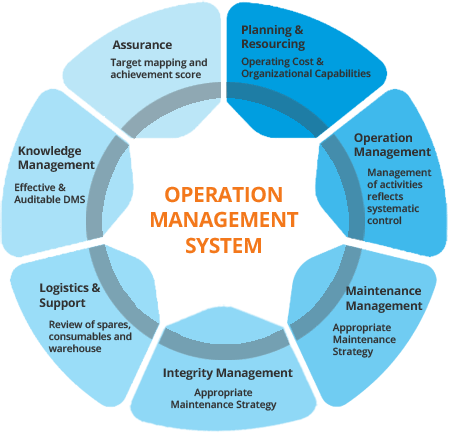

Operation Management System

Encompassing the scope of entire operations of the offshore unit, the Operation Management System ensures adherence to various aspects like Documentation, Logistics, Maintenance, Knowledge Management, and Technical & Contractual Assurance. The OMS is one of the most important reflections of our commitment to managing potential hazards and risks inherent to our operations and achieving excellence in performance and establishes common worldwide expectations for addressing these risks. It defines expectations and requirements for our business lines and guides line management behaviors to manage, prioritize and continuously improve our efforts to protect people and the environment.

Asset

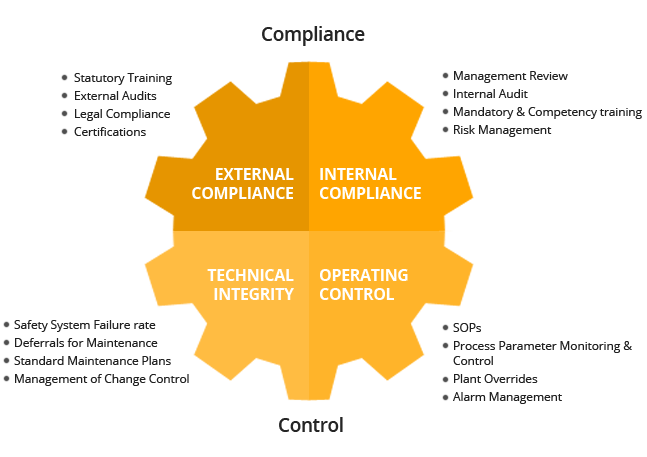

Asset Integrity Management

- Maximizing Reliability, Availability, Maintainability (RAM) of equipment

- Asset performance management

- Cost savings in repairs and replacement by preventing failures

- Effective Management, Monitoring & Control of critical processes (Management of Change (MOC), Override Management System, Root Cause Failure & Analysis (RCFA)

- Corrosion Management: internal and external corrosion control

- Process safety and mechanical integrity services

- Offshore Hazard and Risk Analysis